Advertisement

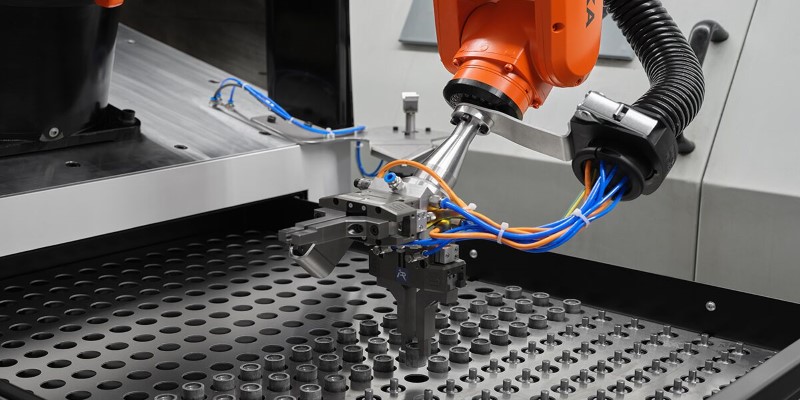

Factories aren’t what they used to be. These days, it’s not just about machines and assembly lines—it’s about speed, precision, and data. And that’s exactly where Schneider Electric and Nvidia come in. Their recent partnership isn’t just another corporate handshake; it marks a serious shift in how smart factories get built, optimized, and scaled. AI has been circling the manufacturing world for a while, but this collaboration is set to bring that future into sharper focus—and faster.

What was once a slow, reactive process is now becoming predictive and self-improving. And instead of tweaking systems after problems arise, manufacturers can now fine-tune performance before the first unit rolls off the line.

Let's begin at the beginning. Schneider Electric is a name synonymous with energy management and automation. Nvidia? They're the computing power folks, particularly in the realm of AI. With them now coming together under the same roof, the agenda is plain as day: create AI-capable factories that learn, adapt, and make more intelligently.

Its. At its center is Nvidia’s Omniverse platform, a virtual space for simulating, testing, and deploying factory models before anything material is even constructed. Combine that with Schneider Electric's EcoStruxure platform, which already offers a lot of support for factory systems, and you have a digital-physical system. Both speak the same language from design through.

It has nothing to do with installing more computers in factories. It involves applying digital twins, data integration, and simulation software to refine every process step. Imagine a factory being born twice—once in a virtual environment, and once in the physical one—both sets of processes continuously learning from one another.

It’s not all theory. Here’s how this setup works in practice:

Using Nvidia’s Omniverse, manufacturers build a fully simulated model of the factory. Every machine, conveyor belt, and power supply is represented virtually. This isn’t just a blueprint; it's a working version of the factory, complete with data inputs. For example, teams can preview how a new production layout impacts throughput without touching a single bolt on the floor.

Schneider Electric’s EcoStruxure platform brings in the real-world side—energy use, machinery status, and environmental conditions. These systems collect and feed live data back into the digital model. If a power fluctuation occurs in one zone, the system can immediately reflect that in the virtual model and trigger alerts or automated balancing routines.

Instead of waiting to see what works on the floor, managers test out workflows, product changes, and even emergency protocols in the virtual model. This saves time, reduces risk, and makes scaling much smoother. For instance, simulating how machines respond to a sudden order spike can highlight bottlenecks before they impact real deliveries.

Based on what the digital model learns, physical systems adjust automatically. Whether that's rerouting power during peak hours or slowing production based on inventory data, the factory isn't just reacting, it's adapting. One real use case: adjusting HVAC and lighting across zones in real time to align with production intensity, cutting waste without manual oversight.

The system doesn’t stop improving. Every new batch of data helps refine both the digital model and the real-world processes. Over time, this leads to better forecasting, smoother production cycles, and more efficient energy use. As more factories adopt the model, shared insights can even guide updates for future deployments, making each one sharper than the last.

Both companies have made it clear: greener factories aren’t optional. With stricter regulations and rising energy costs, sustainability has moved from buzzword to requirement.

That’s where Schneider Electric’s energy expertise plays a crucial role. Their infrastructure is already designed to minimize waste and improve efficiency. But with AI in the mix, these systems aren’t just efficient—they’re optimized continuously. The software doesn’t guess how much energy a process might need; it knows, because it’s measuring it constantly.

This kind of setup allows factories to monitor their emissions in real time, tweak settings to reduce waste, and even shift operations to off-peak energy hours—all without compromising output.

This partnership signals something bigger than a product launch or a tech upgrade. It’s about rethinking the relationship between human input, machine output, and digital intelligence. What Schneider Electric and Nvidia are proposing is a model where factories don’t just run—they learn, predict, and evolve.

The first wave will likely hit sectors that already rely heavily on precision and speed—think electronics, automotive, and high-tech manufacturing. But the underlying model has no hard boundaries. If it works for producing semiconductors, there’s no reason it won’t be adapted for packaging, textiles, or even food production.

And while the big names are behind it, the idea isn’t limited to giant corporations. With time, these tools and platforms will likely become more accessible to mid-sized operations. After all, the whole point of this is scalability—making smarter factories not a luxury, but the norm.

The factory of the future isn’t coming. It’s being installed, coded, and connected right now. With Schneider Electric bringing its energy and automation systems, and Nvidia contributing the computing power to train and run AI models, the stage is set for something more efficient, more adaptive, and more intelligent than anything the industrial sector has seen before.

There’s no single “aha” moment here. Just a steady march toward smarter, data-driven operations that can compete, grow, and sustain—without guessing or gambling. It’s not about adding flash to manufacturing; it’s about cutting out the blind spots.

Advertisement

Machine learning is redefining identity theft detection by recognizing behavioral patterns, preventing fraud in real time, and improving accuracy. Discover how this technology helps organizations stay ahead of digital threats while creating a safer online experience for users

How AI Policy @Hugging Face: Open ML Considerations in the EU AI Act sheds light on open-source responsibilities, developer rights, and the balance between regulation and innovation

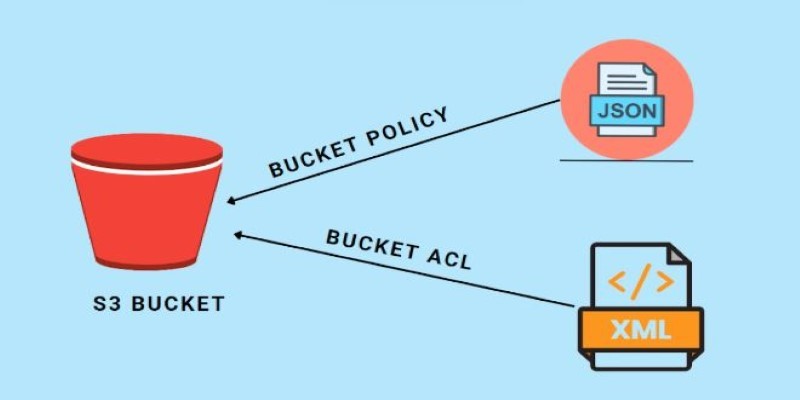

How AWS S3 buckets and security work to keep your cloud data protected. This guide covers storage, permissions, encryption, and monitoring in simple terms

Learn how AI is being used by Microsoft Dynamics 365 Copilot to improve customer service, increase productivity, and revolutionize manufacturing support.

Compare Power BI vs Tableau in 2025 to find out which BI tool suits your business better. Explore ease of use, pricing, performance, and visual features in this detailed guide

How to vibe code with confidence while keeping your applications safe. This guide explains how developers can stay in their creative flow and apply secure coding practices without slowing down productivity or losing rhythm

Discover seven powerful ways AI helps manage uncertainty and improve resilience in today's fast-changing business world.

Generate millions of transects in seconds with Polars and GeoPandas, enabling fast, scalable geospatial analysis for planning

How AI-powered simulation is revolutionizing engineering practices by enabling faster, smarter design and testing. Explore key insights and real-world applications revealed at AWS Summit London

Learn key strategies for prompt engineering to optimize AI language models and improve response accuracy and relevance

Explore the underlying engineering of contextual ASR and how it enables Alexa to understand speech in context, making voice interactions feel more natural and intuitive

Apple may seem late to the AI party, but its approach reveals a long-term strategy. Rather than rushing into flashy experiments, Apple focuses on privacy, on-device intelligence, and practical AI integration that fits seamlessly into everyday life